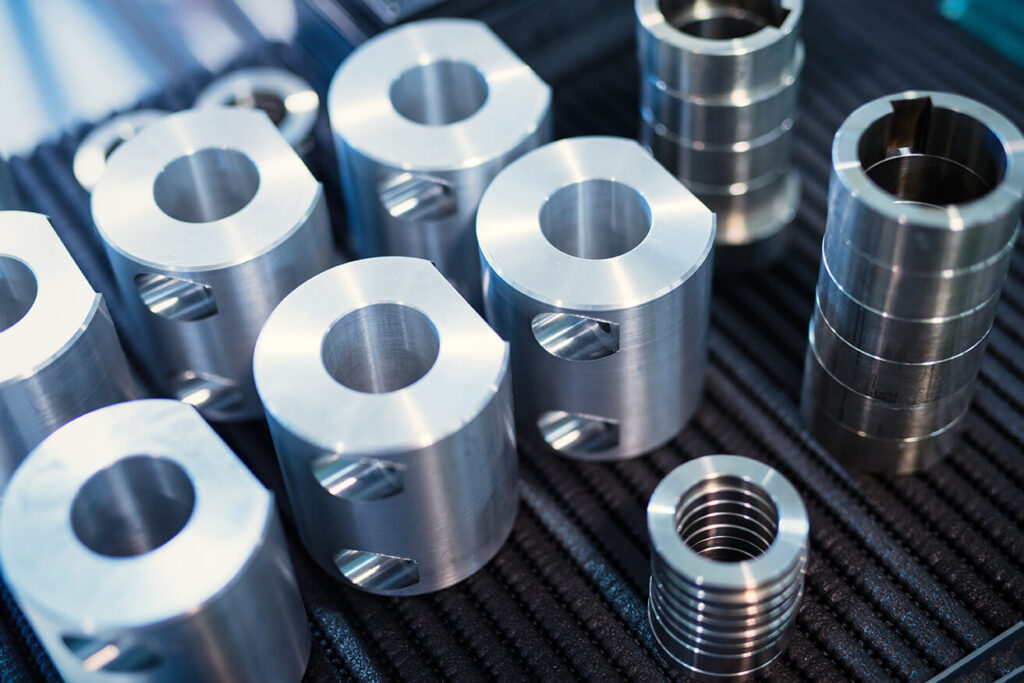

Surface coating and further finishing

The right coating solution for your product.

In order to be able to guarantee the respective function of the turned parts in the long term, we offer a coating solution that is optimally coordinated with the customer.

In cooperation with certified, external partners, we supply, for example, cathodic corrosion protection by electrogalvanizing or zinc-nickel alloy coatings with further improved corrosion resistance. Naturally environmentally friendly with no hexavalent chromating, in many desired passivation variants.

Lead-free tin coatings for optimum solderability are available, as is technical silver plating to reduce contact resistance.

Some possible coatings are listed here. Other surfaces are available on request. Feel free to contact us if you are interested!

Zinc / Galvanizing

With electroplated zinc surfaces, components are protected against corrosion economically and effectively. The layer thicknesses are

depending on requirements approx. 5-15µm. A wide variety of passivations are possible, all environmentally friendly without hexavalent chromium. For example available as

Thin film passivation transparent or blue, thick film passivation, with or without embedded, nano components, sealers (topcoats) or sliding coatings for friction value adjustment.

Zinc-nickel coating

Zinc-nickel is a highly corrosion-resistant alloy coating with approx. 12-15% nickel for heavily stressed parts which, even under thermal load, can be

are consistent. Due to their ductility, the layers can be mechanically deformed without damage. Passivations, topcoats and sliding coatings are available in black and transparent (stainless steel look).

Copper plating

Copper is often used as a base metal in coating systems to improve adhesion, e.g. as an undercopper before subsequent silver plating or nickel plating, especially for components containing lead.

Silver plating

Silver surfaces are mainly used in the electronics industry to reduce contact resistance in mostly thin layer thicknesses of 1.5µ-6µm.

Tin plating (lead-free)

Tin surfaces are often used when components need to be subsequently soldered. Furthermore also for e.g. busbar systems or battery contacts. Our coatings are exclusively environmentally friendly lead-free coatings.

Brass coating

We also coat your components with a brass coating and additionally apply an anti-corrosion oil.

We can also process other surfaces upon request. Please send us a request for this.